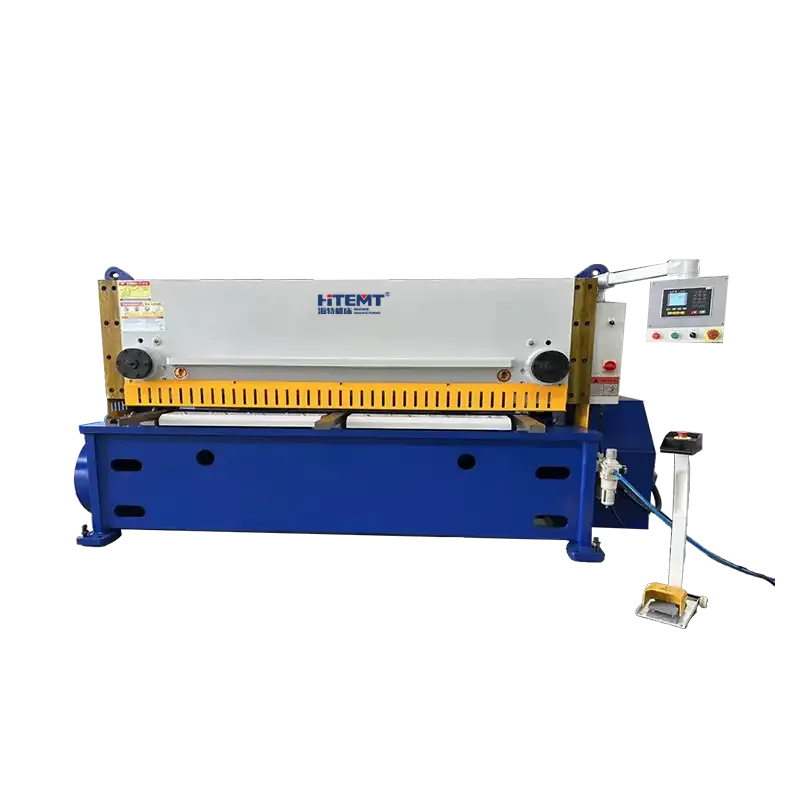

Technical Parameters

Unlike traditional shears that cut from top to bottom, this machine tool employs a bottom-up cutting mechanism, which helps prevent the conveyor belt from being scratched or snagged when burrs appear on the material being cut.

Recommended for use with production lines, enabling rapid integration into customer workgroups.

The power source uses compressed air, producing low noise and ensuring clean, pollution-free operation.

Advanced pneumatic clutch technology

The cutting speed of a hydraulic shear is significantly improved compared to traditional mechanical shears.

Significantly reduces the failure rate compared to traditional shearing machines

Crankshaft drive is superior to traditional straight-shaft drive.

Adopting a three-point supported rolling guide rail eliminates support clearance and ensures shear quality.

Blade gap can be manually or electrically adjusted—quickly and precisely.

The upper and lower blades are made from high-quality tool materials and feature four-sided cutting edges, extending their service life.

The centralized lubrication system minimizes the risk of machine damage caused by operators forgetting to add oil or failing to perform lubrication altogether.

Inquiry Now

If you want to learn more about Hait's products faster, please leave a message, and we will arrange personnel to contact you as soon as possible!

You can also call+86 18751385666 Contact customer service.

* Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.